|

Control of Fermentation Temperatures / Compiferm SoftwareCompinox has available a software solution for monitoring and supervision of fermentation processes in reservoirs of white and red wine, which has been used in wineries since 1990.

This modular system is perfectly suited to each situation and needs of production units / wineries.

Process control Fermentation:

In many fermentation processes, from the existing temperature control by cold or heat, reassembly and maceration, the Compinox provides all the necessary equipment for effective action, control and supervision.

We can thus say that throughout this processes there are three levels:

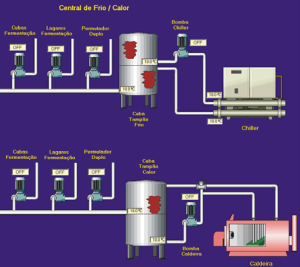

The action on the process - consisting of all the equipment necessary for the development of work - Central Cool and Heat Refrigeration, Maceration Robots, valves ....

Read and process control - Consisting of electronic equipment that makes the analysis / measurement of processes and executes pre-defined orders automatically.

Supervision - With hardware, you can define, record and report all information of operation of the fermentation process.

Key features of the system:

- Ability to control an indefinite number of units of fermentation

- Visualization of the winery in a window of groups of units of fermentation, maceration or reassembly, with a graphical representation of the state of operation (automatic or manual, resting or cooling/heating, providing the temperature in each of the reservoirs ....

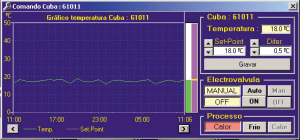

- View detailed status of each tank (reassembly, cooling, ...) with a simple mouse click on the element, with general and detailed process information.

- Configurable for each tank, the fermentation temperature, the time range of reassembly, the temperature differential, the mode of the process - heating or cooling.

- Possibility of manual control of the elements, to run tests or force situations.

- Real time indication of vat temperature and its temperature time graph, thus with the evolution of an information process.

- Database temperature log.

- Form fermentation process, where it is possible to describe the fermentation process, indicating the varieties, characteristics and origin of the grapes, and associate the vat where the fermentation was carried out, and thus have a record of all the fermentation process.

- Optimization of the process, such as connecting or disconnecting a circulation pump automatically depending on whether or not there are vats in cooling or heating process.

- Possibility of transferring the registered data for other applications like Microsoft - Word or Excel.

- Information and record of the operating status and anomalies of the various components, with alarm creation and register.

- Possibility of using the command and display panel with the process as an alternative to the central computer, for ease of operation.

Advantages:

- Increased quantity and concentration of information available to the operator and the winemaker.

- Ease of operation and configuration of operating parameters of the system.

- Automatic recording and customized reporting.

- Possibility of analysis of this information after fermentation by other tools such as Microsoft - Excel.

- Reduction of wiring required, resulting in increased system reliability and lower maintenance.

- Automatic detection of abnormalities, with alarm and registering them.

- Ease of expansion due to the modularity of the system.

- Use of control equipment of high quality and independent modules.

|